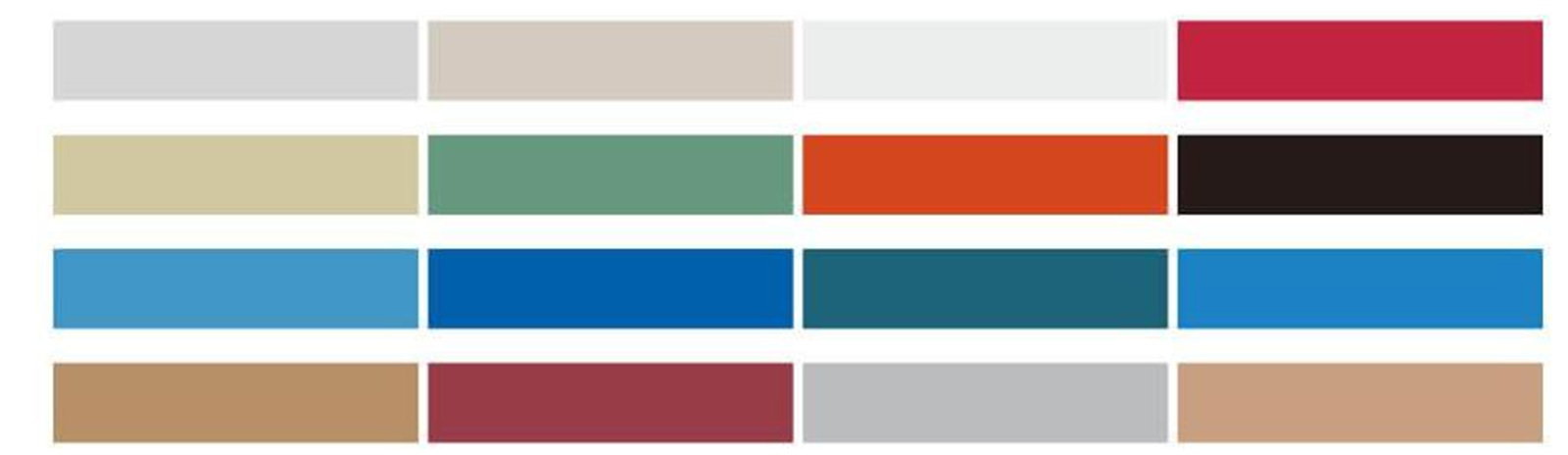

The common colors are as follows. If you need other colors, we can customize them for you.

Parameter

Advantages

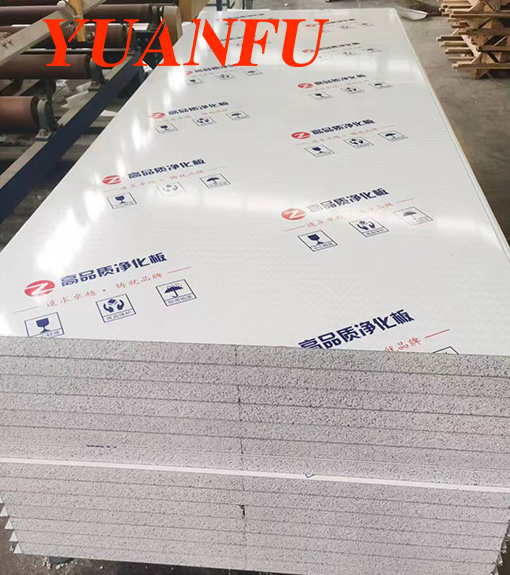

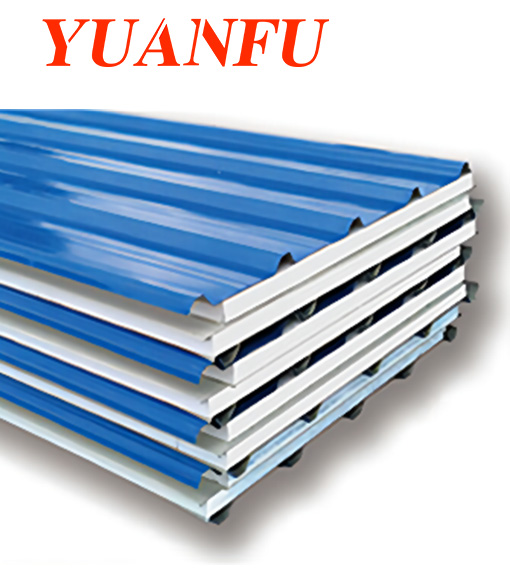

1. Good fireproof performance, moisture-proof, corrosion resistance, Environmental protection.

2. Strong and light weight materials suitable for the construction. It's easy of installation and labor cost saving.

3. Thermally efficient rigid foam insulation used as the core material of sandwich panel. Excellent high temperature stability and low temperature application.

Installation

1. First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2. Before the installation of sandwich panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3. Before installation sandwich panel, it should first mounting plate bottom water retaining plate and the bottom of the window to block water board, water retaining plate and wall frame beam connection with self tapping screw fixation.

4. Sandwich Panel links with ground.

Lateral links: fixed sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed sandwich panel.

Application

It widely used for steel structure workshop, steel house, suburban housing, villa, kindergarten, model house for apartment, commercial building, remodeling of old structures, warehouse, steel structure house, workshop, work plant, airport, cold storage, mobile house. The almost typical applications include commercial buildings, sports halls, warehouses and power plants. The panels are also suitable for food industry construction and clean room applications.