.jpg)

Purification board, also known as clean board, is a composite board with color-coated board, stainless steel and other materials as the surface layer. Due to its unique dustproof, anti-static and antibacterial effects, it is widely used in purification engineering fields with strict requirements on indoor environment such as electronics, pharmaceuticals, food, biology, aerospace, precision instrument manufacturing, scientific research, etc.

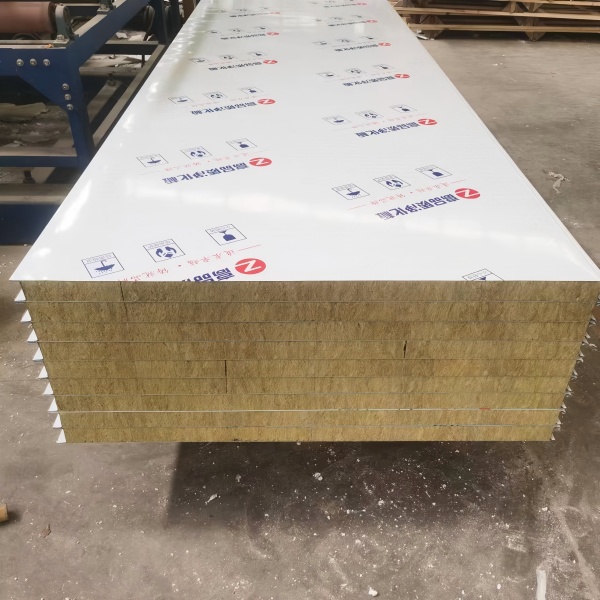

The clean board has three layers, both inside and outside are galvanized or aluminum plates, and the core material is filled with rock wool, aluminum manganese magnesium, polyurethane, rock wool, glass magnesium board,

EPS and other types of core materials to meet different cleanliness requirements. Due to its good dustproof, anti-static and antibacterial effects, it can be used in purification engineering fields with strict requirements on indoor environment, such as electronics, pharmaceuticals, food, biology, aerospace, precision instrument manufacturing and scientific research.

Application

Clean room wall panels can be used as exterior walls and interior partitions, and can be installed vertically or horizontally on single-span or multi-span structures.

Description

Clean room wall panel products are widely used in pharmaceutical, electronic, aerospace, military and other industries, using HPL clean room wall system. The system is connected by aluminum profiles, with a simple structure and easy disassembly. Perfectly matches the clean room doors and windows, making the clean room more beautiful.

Clean room is a special designed room to exclude the particles in the air, bacteria and other harmful air pollutants, and the indoor temperature, cleanliness, interior pressure, air velocity and air distribution, noise, vibration, and lighting, static control within the scope of a certain demand. That is no matter how the outside air conditions change, its indoor all can maintain the original set requirements of cleanliness, temperature and humidity and pressure performance characteristic.

Description

The cleanroom wall panel products are widely used in pharmaceutical, electronic, aerospace, military and other industries, using HPL cleanroom wall system. The system is connected by aluminum profiles, with simple structure and easy disassembly. The panel adopts sandwich structure and can be filled with materials such as rock wool, paper honeycomb, aluminum honeycomb, etc. It perfectly matches the cleanroom doors and windows, making the cleanroom more beautiful.

Pharmaceutical Industry Grade B

Advantages

1. The structure of Yuanfu clean room wall system is uniform and dense, and any point of the board is strong and durable. The surface of melamine board is very rich in tones, patterns and textures, so it can be used outdoors with corresponding strength requirements and appearance requirements.

2. The product is beautiful and durable, and the impact absorption performance and special manufacturing process make it have certain shock resistance.

3. Clean room wall panels have excellent impact resistance, water resistance, moisture resistance, chemical resistance, heat resistance, wear resistance, chemical resistance and weather resistance. Sunlight exposure will not cause discoloration or fading. In addition, the product is not easy to get dirty, easy to clean and easy to maintain.

4. The pharmaceutical industry often uses dry or wet gasification hydrogen peroxide disinfection and sterilization systems. Due to the strong permeability of hydrogen peroxide, its intrusion can reach the submicron level, and it will penetrate from the gaps on the surface of the clean board and the surface of the clean door to the inside, causing bulging, shedding, paint tearing and other phenomena on the surface of the clean room wall and clean door. HPL cleanroom wall panels are resistant to vaporized hydrogen peroxide (VHP) disinfection.

Maintenance Instructions

1) General contamination can be wiped with a normal damp cloth.

2) For minor stains, use warm water and neutral soap to clean the surface.

3) For stubborn stains, use a high-concentration detergent to clean, or wipe with a solvent such as alcohol or acetone.

5) After cleaning, wipe with a soft dry cloth.

6) Do not use a steel brush or polish containing abrasives to clean, as this may scratch the surface of the board.

7) Do not use sharp and hard objects to leave marks on the surface of the board.

8) Do not place overheated objects directly on the surface of the board.

9) Do not use abrasives or non-neutral detergents.